Home » Fiche technique » Deep Silicon ICP Etcher

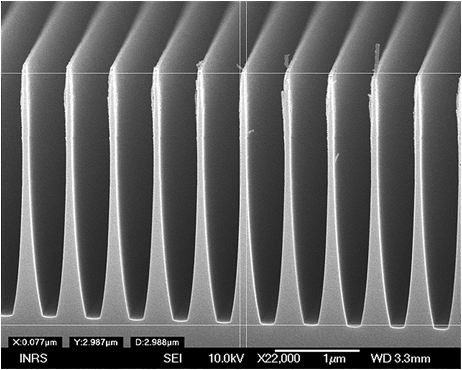

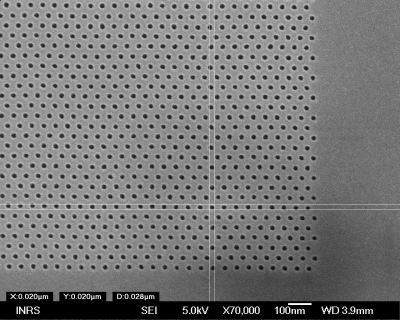

The Plasmalab system 100 is a high density plasma etcher configured for the high aspect ratio etching of Silicon using either Bosch or cryogenic processes.

• ICP 380 mm high density plasma source (2MHz, 5kW generator)

• 240 mm lower electrode with automatch unit (13.56MHz, 600 W)

• Variable height cooled/heated electrode (-150° C to 400° C)

• Wafer clamping and He backside cooling

• Sample holder: from pieces up to 200 mm wafers – 5” plates

• Typical process pressure: 1 – 100 mtorr

• PC controlled and programmable recipes

• Fast MFCs for Bosch process with smooth sidewalls

• Available gas : SF6, C4F8, CF4, O2, H2

• Dual beam laser interferometry end point detector optimized for step detection

• Rapid loading (loadlock)

• Chamber cleaning done through an integrated recipe

• Anisotropic etching of 300 um deep trenches on silicon for the fabrication of MEMs devices

• Through wafer via processing