Manufacturer : INRS

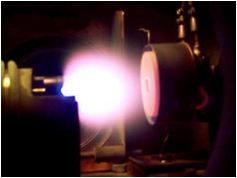

Role of the equipmentThe pulsed laser deposition system consist of a laser focused on a target that is placed inside a vacuum chamber. It allows the deposition of a large number of materials like metals, ceramics and oxydes with an independant control on the deposition temperature and the background pressure (wich can be oxygen, helium, nitrogen, etc...). On most cases, the resulting thin film has the same stoechiometry as the target used.

Technical specifications• Laser source 1: PulseMaster 848 from GSI Lumonics (100Hz).

Accessories• Possibility to use a background pressure (of O2, Ar, H2, He or N2).

Examples of available processes and services• Deposition of ferroelectric (BST, PZT, PLZT, CBN, …) |

|